About us

Founded in 2010, Jiubang Heavy Industry Co., Ltd. has become a leading manufacturer of special vehicles and heavy machinery in China. The company has grown from obscurity to a national high-tech enterprise with strong R&D, production and sales. Passed ISO9001, SGS, CE.More than 100 patents.

Factory area

2 plants, 120,000+ square meters

employees

More than 350 employees, including 35R&D personnel

production capacity

Annual production capacity of 6,000 vehicles

The company’s headquarters has 35 technicians, including 10 middle and senior titles, provincial and municipal level science and technology personnel 5 people. Among them, there are 10 people with middle and senior titles, 5 provincial and municipal scientific and technological experts, 5 scientific and technological experts who are members of national and industrial standard committees, 3 members of national and industrial standard committees, and 1 high-level talent from Shandong Province.

jiubang group attaches great importance to scientific and technological innovation, constantly strengthen scientific research investment, actively carry out scientific and technological research, strengthen scientific research investment, pay attention to the construction of the enterprise innovation environment and R & D talent team, attaches great importance to scientific and technological innovation professionals training, give full play to the leading and supporting role of talent.

From the laboratory to the factory, from the factory to the market, and then from the market back to the laboratory. We constantly track and understand the use of products. On the basis of conventional R&D process

On the basis of regular R&D process, trial production process and test of trial production process, we focus on components, systems, the whole machine and appearance, and “endless grinding” is thus unfolded

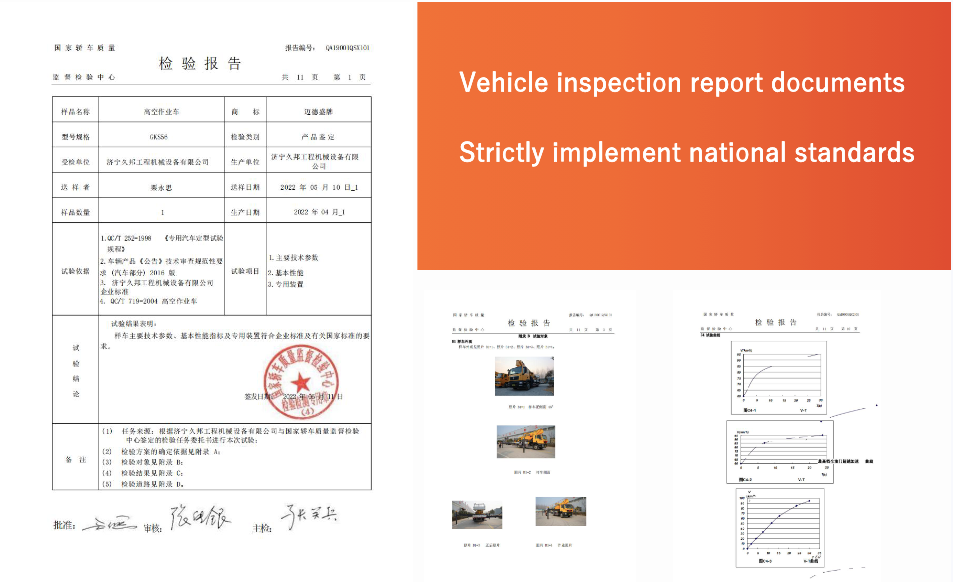

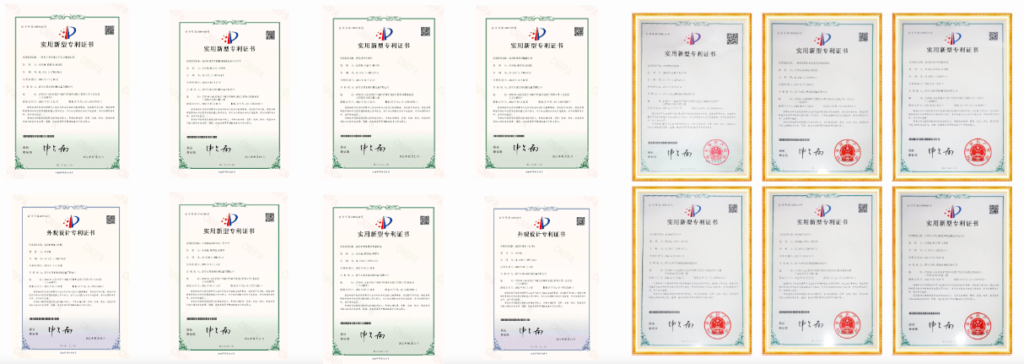

Corporate Honor

Honor Certificate

Patent Certification

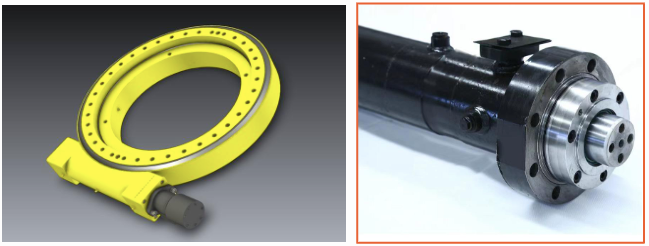

Raw materials supply

Procurement link

The supply of raw materials is screened at all levels. Key components are all from domestic and foreign first-tier

brands, and non-critical parts are from first-tier domestic

suppliers to ensure product quality from the source.

Warehousing center

Establish a large-scale warehousing center that can meet the annual output of 6,000-7,000 special vehicles, and use EPR software to standardize management of all production departments, which not only improves internal supply efficiency, but also greatly reduces risks such as mixed use,misinstallation, and missing installation of parts.

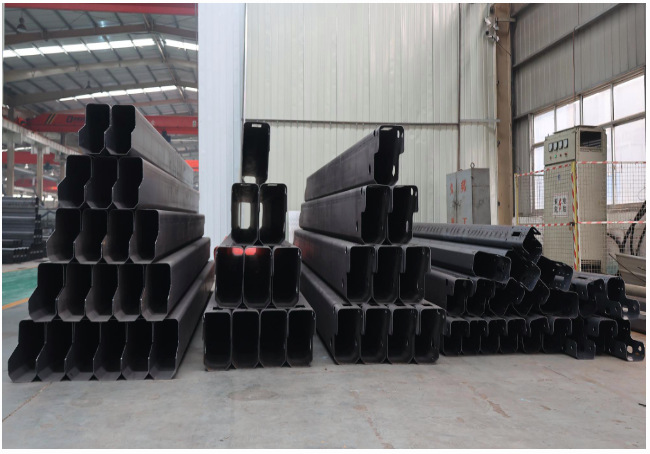

Production Strength

laser cutter

The largest local 30000W ultra-high power laser

cutting machine, which can process parts with

different slopes and thicknesses to meet the high

-quality standard production process requirements. Has three 20000W and two 6000W

laser cutting equipment, a total of 6 laser cutting

equipment, supplied Cutting of different parts

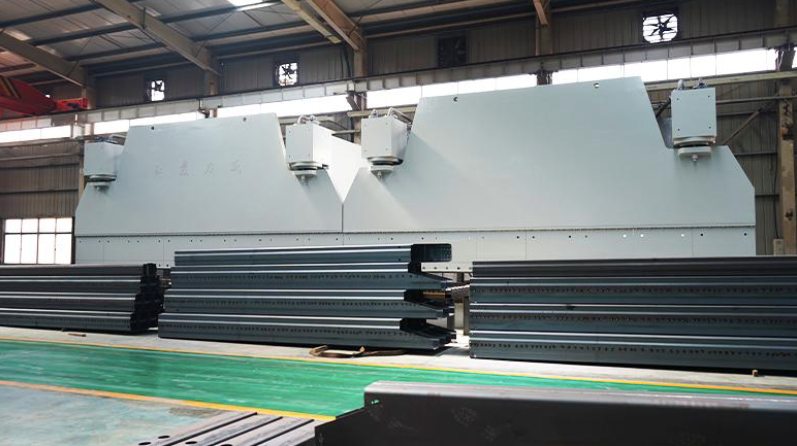

CNC bending machine

The company has the largest local CNC bending

machine, which can provide a maximum bending

capacity of 2400T/18 meters to meet the processing needs of ultra-large equipment and

customized equipment. It also has a total of 7

bending equipment such as 800T and 500T

Welding

The company has 60 welding stations and 5

welding robots. Key parts use manual-assisted

welding robot welding equipment to ensure the

precision and integrity of the welding parts. Each

welding station welds similar parts to enhance

the proficiency of the welder masters. degree to

ensure welding efficiency and quality.

Boring/milling/drilling/sawing and other machining Boring and milling machines use high-precision bearings and guide rails for machining processes such as boring and other parts, with high precision and stability, which can ensure high-speed operation while Maintain high-precision processing at all times.

variety of processing operations can meet different processing needs,The CNC system used in the equipment It can accurately control the processing process, realize intelligent control,

reduce manual intervention, and improve Processing quality and stability.

Painting process

Have large spraying workshop, and all parts are treated with sandblasting, which can clean and roughen the surface of the

substrate and improve the mechanical properties, fatigue resistance and paint adhesion of the workpi Painting process ece

Assembly line

The company has internationally advanced 10 assembly lines and 6 pre-assembly lines. All accessories are assembled without flooring, and personnel are under standardized management to reduce unnecessary performance losses of components during assembly and ensure high precision and high quality of products.

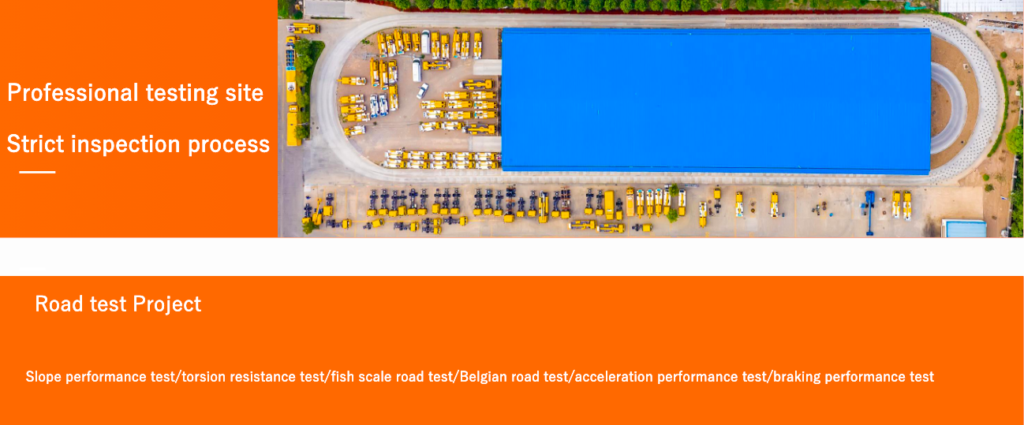

Quality Inspection Process

Technical debugging

Inspection Report